Scope of Delivery

- 1x Sedimentator for Sluice System 10 cm: ca 80cm x 45cm x 15cm LxHxB

- 1x hose connection for 1 inch (25mm) hose

- For channels up to 14cm outside dimensions

Recommended accessories:

Sedimentator for washing trough 10cm

What is a sedimenter?

A sedimenter separates a mixture of water and foreign bodies by allowing the heavier components to sink (sediment). The water freed from this ballast can now be used further. The main advantage is two points:

- No stones in the pump : The sedimentator prevents stones and magnetite from entering the tank for the pumps. This in turn significantly increases the life of the pumps and saves a lot of trouble due to contamination in valves and hoses.

- The funnel shape of the sedimentizer allows the material to be completely pumped out at one point. This allows the sedimenter to be completely emptied easily.

Functional description Sedimentator

The sedimenter is initially designed for sand / water mixtures, but can also partly remove lighter suspended particles from the water stream. A perforated plate serves as a throttle and brakes the water flow, on the other hand, the perforated plate also distributes the flow over a very large cross-section so that the maximum flow velocity in the system is minimized. At low speeds, solids present in the water can no longer remain in the flow and sink downwards.

The sedimentator is optimized for the use of a jet pump. The two steep flanks and the chute in the sedimentator center the material like a funnel at the suction point of the jet pump at the bottom of the sedimentator. This can be emptied without residue (depending on the material). Of course, the sedimentator can also be operated without a jet pump, which of course is not necessary for the pure function of the device!

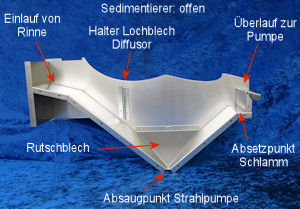

In the picture above you can see the sedimenter in side view. On the upper left is the support of the washing-out trough, including the support for the frame. Further to the right in front of the holder of the throttle is a hole, into which a 25mm curved hose nozzle is mounted. Here, if present, the overflow of the feeder can be installed. The feed water of the jet pump coming from the feeder is fed back to the system at this point and also cleaned of any substances. The support for the jet pump can be seen in the center. The two double rivet connections below show the places where the holders for the jet pump are mounted on the inside. To the right, the water then flows back into the collecting tank of the pump. The device is designed for the use of the wash-out system frame, but can also be quickly integrated into the own system without this frame. If necessary, a hole can also be drilled at the suction point for a separate outlet through which water and sand can be drained.

In the above picture, a cross-section through the sedimentator is visible, so the front cover plate is missing. The water is directed from the left into the sedimentator and then slides over the flat ramp, which is still above the water level so that nothing is left here, in the central, funnel-shaped part. Before the throttle plate, the water is decelerated and flows, the material is carried along, through the perforated plate. The current is now so weak that the sand and all heavier components settle at the bottom of the sedimenter. For smaller quantities, the skid plate ensures that the material is gathered at a point so that it can be sucked off. In the right part of the sedimenter, the water accelerates again (nozzle effect) until it leaves the system when the pump is overflowed. Before the overflow, a settling point for light components is placed. Floating parts will be collected here, but not all suspended materials can be stopped.

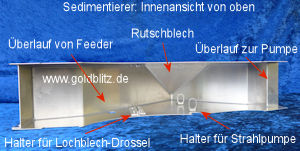

Here again a view from above in the ready assembled sedimentator. The holders for the jet pump are good to see. All rivet connections below the waterline are riveted with sealing rivets and additionally sealed with silicone. For the sedimenter, I use transparent silicone of the usual quality for visual reasons.

This product was added to our catalog on Wednesday 01 February, 2017.