Scope of delivery Full Set:

- 1x Headboard for Sluice System 10cm , with water damper and rack adapter (all sets)

- 1x Hopper Box with connector 25mm and 10mm (Inside) (all sets)

- 1x Basic Tubing Pump to Hopper (all sets )

- 1x Sluice Body 10cm x 70cm (all sets )

- 1x Hose extension for Jet Pump (Standard + Full set )

- 1x Jet Pump (Standard + Full set )

- 1x Feeder (Standard + Full set )

- 1x Sediment (Full set )

- 1x Funnel (Full set ) We deliver Version II Cleanup Funnel, there is no more need for the additional adapter!

- 1x Rack (Full set )

- optional: Knurling Kit for easy disassembly of the centering plates or for easy mounting of the water damper. (4 pieces of knurled nuts, 4 head of cylinder head screw M4, 8 pieces of washer, all stainless steel)

- optional: Miner's Moss approx. 100mm wide and 300mm long as a flow booster (without holes)

- optional: Inlay for Sluice, glued and sealed

Recommended accessories:

Overview of the sets

All sets are designed for a grain size of 2mm when a jet pump is used! It is strongly advised to urge the material into fractions, which makes the washing easier! We recommend either a fraction of 2-0,5mm and a <0,5mm or a fraction of 1-0,2mm and one of <0,2! The larger material (ie> 2 mm or> 1 mm) is washed by hand (should be a children's play at 1mm).

| component |

Basic Set |

Standard Set |

Full Set |

| Sluice Body |

Yes |

Yes |

Yes, 2 pieces |

| Headboard with end piece |

Yes |

Yes |

Yes |

| Hopper Box |

Yes |

Yes |

Yes |

| Basic Tubing |

Yes |

Yes |

Yes |

| Tube Expansion Jet Pump |

No |

Yes |

Yes |

| Jet Pump with suction piece |

No |

Yes |

Yes |

| Feeder with holder and bottle |

No |

Yes |

Yes |

| Adapter for Sluice Bodies |

No |

No |

No |

| Funnel Pack |

No |

No |

Yes |

| Rack, height adjustable |

No |

No |

Yes |

| Sedimentierer |

No |

No |

Yes |

| Maximum grain size |

2mm |

2mm |

2mm |

| Discount against individual prices |

ca. 20% |

ca. 22% |

ca. 24% |

There is a instructions for the washout system 10cm , in which the components once again accurate (About 150KB, PDF).

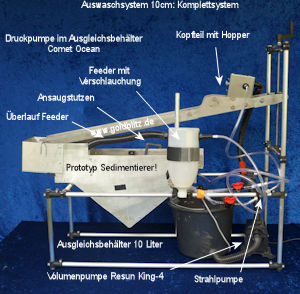

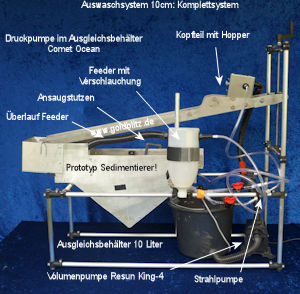

The Complete Set

The complete set is designed for those who want to wash out complex material and fine gold in as few passes as possible. In addition, a complete Cleanup-Sluice for the Wash-out system 10cm is the same! This means that every possibility of combining the wash-out system 10cm is open! On top of that there is the as well as a suitable Feeders (a functional storage container). With these two components, it is possible to optimally adjust and control the material feed into the system. The plant can therefore be operated without manual feed, they can now handle more important things (weighing gold nuggets, polishing gold bars, taking a bath in gold dust). Only at the beginning and at the end of the process is their presence necessary (in between, only to the tinkling, if one already sees gold!). The washing process with this set is as follows:

- Fill new concentrate : The feeder is filled with a new material, which is only 2 mm thick. The feeder can be filled to 2/3, which is about 3-5kg of material, depending on the concentration and contents. If you want to avoid unnecessary pain, you should use a magnet (eg ) Gold flash magnetite magnets ) as much as possible remove the magnetic parts! The less magnetite in the system is made easier. The pump also thanks you.

- Wash material : The volume pump is switched on. The jet pump is placed and started in the feeder (either with a volumetric pump or with its own pressure pump). The volume flow is now set with the valve of the jet pump. There should be no overload on the fishing system.

- Cleansing the launder : The material has now been completely fed from the feeder through the launder. The jet pump can now be switched off by closing the valve of the pressure pump or deactivating the pressure pump (see step above). The wash-out channel runs for some time until the amount of material in the gutter has decreased significantly. Now either to the "Final" step or continue with the next step.

- Next passage run: Because there may be restraint systems that focus on the quality of leaching (ie the purity of the remaining gold) rather than the complete extraction from the concentrate (example: Goldblitz Auswaschmatte) a further passage may be desirable. The jet pump is now pulled out of the feeder and inserted into the intended support point in the sedimentator. The feed hose (8 mm) is transferred from the hopper to the inlet of the feeder. The jet pump is started and the sedimenter is emptied into the feeder. If all material is in the feeder, proceed to step (2). You must make a decision before the following step: Do you want to leave the gold already in the gutter there or do it before the next step? This depends on the purity of the concentrate obtained so far, as well as on the size of the gold (is there a risk that too many flakes will be washed out again?). If you prefer to wash the gutter, we recommend the purchase of another gutter, which is much faster! In addition, it would be possible to build a modified body for the second pass ("for problems").

- Final : You now have all the gold in the gutter. If the gold is as pure as they want it to be, they are finished (Tusch!). Otherwise, a final cleanout is carried out: Thoroughly clean the gutter with the spray jet. Under the centering plates of the head part, smaller magnetite bobbins are often attached. It is important not to have any "deaf" sand in the system. Open the water damper for a short time, to remove any stumbling blocks. Now gradually increase the slope of the trough until they have reached the desired washout result. For a gutter with a Goldblitz wash-out mat, proceed as follows: Turn 10 turns on the height adjustment (15mm). Wait 2-5 minutes and then take them into the stream of water leaving the gutter. Do they still feel many grains? Then wait. Otherwise increase the slope again until the desired purity is achieved. TIP: If the material is held in the edges, proceed as follows: Turn the slope completely to zero (or to minimum). Take a small brush (10-15mm) and start it at the gutter exit, push the material from the edges of the gutter about 20mm into the gutter. If both edges are cleaned, restart the final cleanup. Whoever does this from "top down" sheds a lot of gold! Always work against the flow from bottom to top!

- Rework : Now turn off all pumps. Remove the material from the collecting container and clean the drainage channel. Keep in mind that stainless steel can become rusty when exposed to less noble steels! . Dry all hoses, avoid algae formation.

Here is a productvideo on YouTube

It is highly recommended to read the Feeder and the Beam pump and Sedimentator to read and look at the pictures there!

Upgrade kits

Since we realize that the spoiled choice (or: the enjoyment of shopping) is often reduced by the phrase "crap, since I bought the wrong one", we offer an upgrade set: Upgrade to the next higher or higher set Will get a discount of 10% on the sum of the individual prices! This also applies to sets that are not yet fixed (maybe the "Vollautomat" comes out ...). These upgrades are only available for the 10cm wash-out system. If you want to upgrade from the basic set to the complete set, order both upgrades (basic to standard and standard to complete)!

| Set |

After Set |

component |

| Basic |

Standard |

1x tube expansion jet pump, 1x jet pump, 1x feeder |

| Standard |

Complete |

1x trough, 1x adapter, 1x funnel, 1x rack, 1x sedimentator |

Explanation of options

knurled Set

The following options are available for the knurling set:

- Normal : The header is shipped as shown. Anyone wishing to solve the centering plates, for example, Has flipped a funnel and also feeds material into the funnel, has to reach the tool (M4)

- Knurling Kit: It's easier with the knurling kit: four M4 knurled nuts, four M4 cylinder head washers and eight 4mm stainless steel washers. Now the centering plates can be changed without tools and also the clamping part of the water damper can be converted to knurls. This means that you are quickly equipped everywhere.

- Double pack knurling kit: Two knurling packs are supplied, which can be used to convert centri plates and the clamping part of the water damper. Two knurls then remain in reserve (for example, for universal connection).

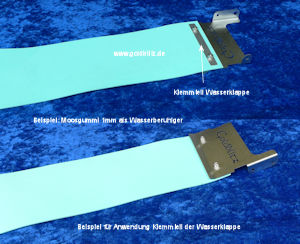

Moisturizing water from moss

The following options are available for the watercooler:

- Without mat : The water damper is supplied with clamp and cylinder head bolts, but without additional mat. If necessary, this can be made of soft, floating (!) Material.

- Moosgummimatte A piece of moss (color can be changed!), With the approximate dimensions 10cm width and 30cm length. This can be clamped under the water flap and serves to soothe the flow. We recommend! But everyone swears for a different material, so only as an option.

Inlay for sluice body

Please read the explanations in the article sluice body for washout system 10cm .

Application examples (all sets)

Below you will find some suggestions and application examples for the wash-out system 10cm. Please note that not all sets contain all the components required for this.

Help for pump selection

Basics for pumps

The set contains the components necessary for the operation of a wash-out system. Only one pump is missing with an inch connection (hose spout 25mm) as well as a compensating vessel (for example a large mortar). Do not search for electric pumps in our shop, we do not sell them! The following basic data would be recommended for this pump:

- Pump performance : It is possible to read roughly the total performance, whether a pump is sufficient or rather not. I would use pumps with a power over 50 watts as a volume pump, which often makes it difficult. Pressure pumps should be in the range 20-60 watts. Exceptions here are diaphragm pumps, which often create very high pressures at low power and are also very suitable for application as a pressure pump (but expensive!).

- Pumps pressure and flow: Unfortunately, this is the worst pumpable pump value, so here is a brief info about the pump: two pump parameters are given "Or 0.5 bar) and the maximum volume flow (eg 5000 liters per minute). Unfortunately, these data can be seen at the same time in the least cases! For example, many pumps at half the nominal height (example above: 2.5m) create less than half of the specified maximum flow rate (example: 2000 liters per minute). This relation is given in the respective performance diagram of a pump which only shows very good pumps in public (because often grottenschlecht). Only as an auxiliary position: at maximum discharge height, the flow rate is always zero (!). Thumbnail: A very simple pump should cost about 50 €, less is not to be done!

- Connection type : There are submersible pumps (these are immersed in a tank filled with water) or freestanding pumps with both an inlet and a drain. Ultimately, it is taste, what you buy here, I have a freistegend pump. For a submersible pump you save the tubing of the feed line, which is not really a big point. The freestanding pump does not tend to be soiled and is better accessible.

- Connector size : The base tubing is 25mm or just an inch. It is therefore important to ensure that the pump has a hose gland with an inch nominal diameter (ie for hoses with an inch inside diameter). Please do not confuse with the thread at the output! This may be e.g. 3/4 inch and the hose spout still has an inch!

Number of pumps to be used

Right at the beginning: If you buy a decent pump (should be so in the price range 100 € -300 € (!), Can drive with a pump the entire plant. Such pumps are available as "garden pumps", the power is 200 (I'm old-fashioned and call it "220V," everyone knows what is meant). "Often there are already pumps in the household, with these you can start first (See there!), It often makes sense to operate two or even three pumps in parallel due to the cost of solenoid valves:

- One pump is used for the base package. Here, only one volume pump is necessary, there are no jet pumps. From the standard package you can decide whether you want to drive with one or two pumps: a volume pump provides the water, a pressure pump ensures the operation of the jet pumps.

- Two pumps are used if the volume pump is too weak to operate the jet pump at the same volume flow (standard set or complete set). This should be the case if an aquarium or bilge pump is used as a volume pump. An additional pressure pump with low volumetric flow makes sense. All in all, it is simply faster in many cases if both a volume and a pressure pump is used.

- Three pumps make sense only from the complete package and only when the "fully automatic" is to be implemented. The third pump drives the (optional) second jet pump, which transports the material from the sedimentator into the reservoir of the feeder without having to hang the jet pump.

One therefore distinguishes between two pump types: the volume pump and the pressure pump.

The volume pump

As a volume pump, in many cases, a better aquarium pump is sufficient with a power consumption of approx. 40 watts. These are simple impeller pumps, partly as a submersible pump, partly as a freestanding version. The recommended value should be a maximum volume flow of around 3000 liters per hour. I would make sure that a grain size of 2-5mm can be transported, especially if you do not have a sedimenter.

The pressure pump

The pressure pump is intended to drive the jet pumps. I have done this in many cases with my impeller pump, so without a second pump. The impeller pump I have chosen "a number bigger" (60-100 watts) and when activating the jet pump the volume flow is reduced, in order to have more pressure on the jet pump. This is how you can make it more fun, however, to buy a second pump for this. Such pumps ("water pump for mobile homes") have usually 12V supply voltage and a nominal volume flow of 12-25 liters per minute (fantasy values, which were determined by a mad marketing department!). In reality, these pumps are sufficient to drive the jet pump quickly. Important is the maximum pressure that the pumkin can deliver. The nominal pressure should not be below 0.7 bar, maximum 5 bar is permissible (then the valves burst). Such a pump is available between 25 € and 50 €. A pressure pump is sufficient for many jet pumps, as long as they are not operated simultaneously.

The jet pump

To increase the confusion factor, I now explain why I am constantly talking about a "jet pump", there is still a pump. Oh yes, there is. The jet pump is a simple (lied!) Flow system, which comes without electricity and without moving parts. The enormous advantage of this pump is that it can transport a mixture of solids and a driving medium (in our case water, but it would also work with compressed air). The pump is driven by ... water from the pressure pump. Please read the product description of the Strahlpumpe in our shop for more Info.

This product was added to our catalog on Wednesday 01 February, 2017.